How To Clean A Dirty Soldering Tip

Alternatively you can use a special polishing bar particularly of the tip is corroded or extremely dirty.

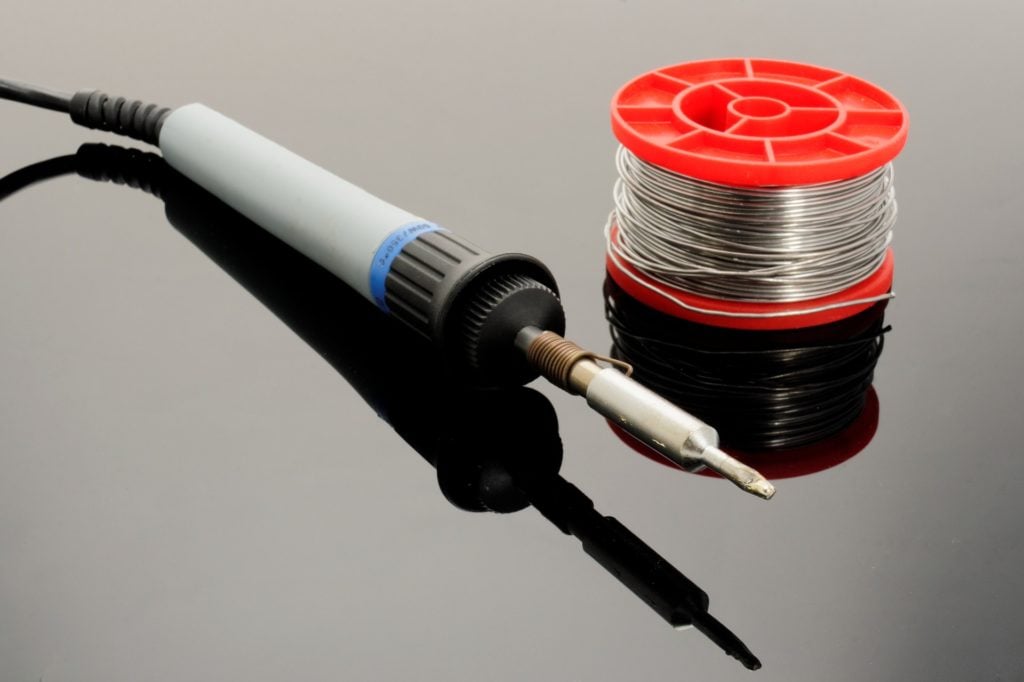

How to clean a dirty soldering tip. If the tip loses its tin you want a product called tinning salts or sal ammoniac to restore wettability then re-tin with your usual solder. Fit the new tip into the retaining sleeve and screw it back to the heating element. How to clean and care for a very dirty soldering iron tip - YouTube.

In this case you have to damp down the steel wool and rub the metal tip of the soldering iron and as a result it will remove the rust and stains. If there is a significant amount of flux left on the piece or dirty solder consider using a soft brush to help with scrubbing. Cleaning and maintaining soldering tips ensure its longer life.

Cleaning the iron is usually done with either a damp sponge or brass turnings. Cardboard works in a pinch. Your cleaning method will vary based on the status of your soldering iron whether it is currently hot or coldIf your iron is dirty but still hot set it as.

This is essential for the transistors and ICs. Once your iron is heated up for a job wipe it on a wet sponge to remove old solder and apply solder to the tip. After trying both the sponge and flux to clean the tip of your soldering iron sal ammoniac would be the next step if the others didnt work.

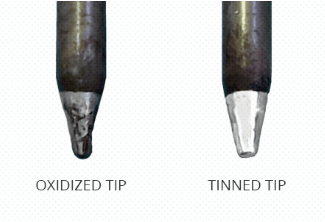

The trick is to make sure the parts to be soldered are clean. This should lead to a clean shiny tip ready for use. To clean dirty surfaces and stains from the iron tip we highly recommend using a steel wool ball.

Its a bunch of thick tinsel-like wires intertwined. A polyurethane foam bar with embedded abrasives which is used to polish the working end of the tip to remove surface oxides. If you choose to use a brush do it only on the solder.