Soldering Iron Tips Wear Out

Soldering iron tip manufacturers have.

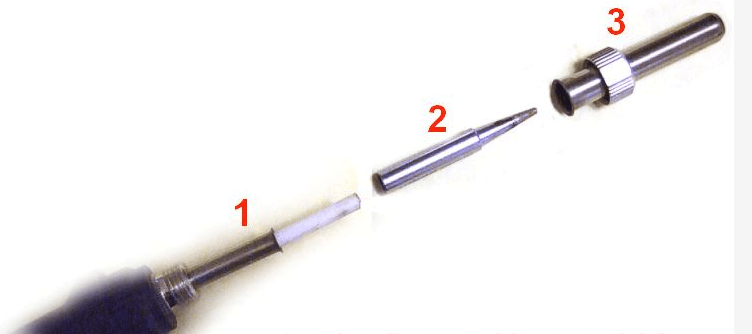

Soldering iron tips wear out. Heres what you can do to keep your soldering iron working for years to come and prevent badly maintained solder tips from affecting your work. Ive got both JBC and metcal and use the Metcal mostly because tips are a lot cheaper so i can afford to have a lot of different tips. First theres the one commonly known as a b-series tip.

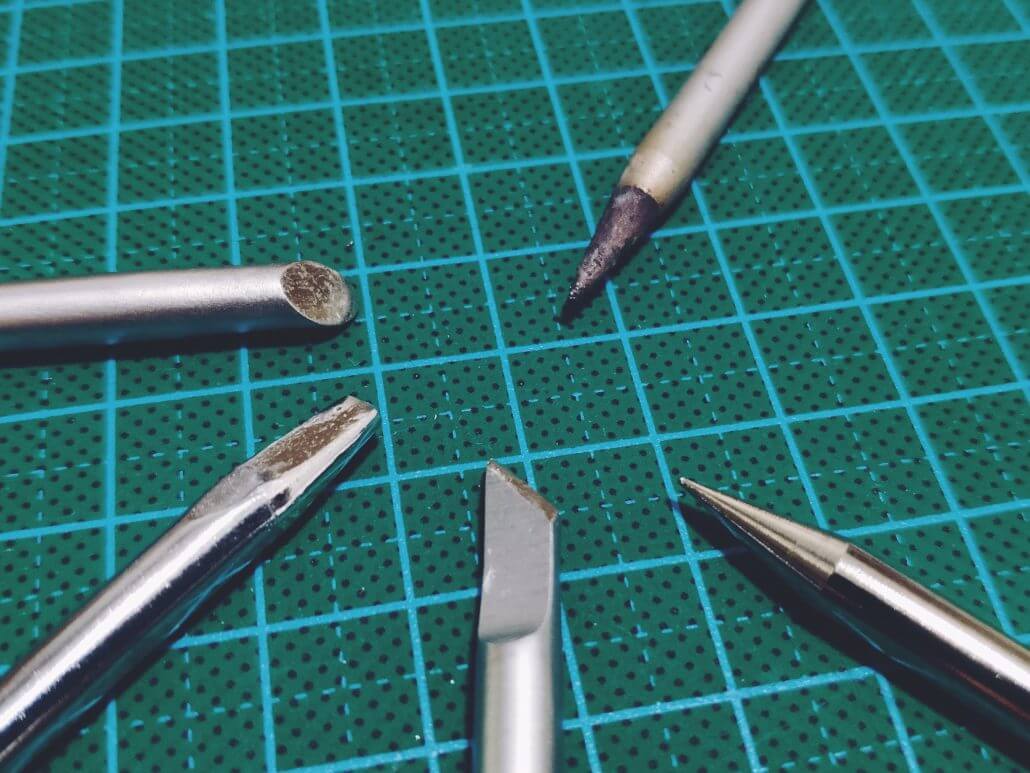

Do not use the tip tinner on a new or used tip that will still tin properly. Soldering iron tips wear out over time and unfortunately if your tool fails to transfer heat to the connection point effectively then it must be deemed unreliable and ultimately expendable. The knife soldering iron tip comes with a slanted tip resembling the shape of a knife.

Corrosion from acidic or highly aggressive fluxes. Eventually they wear out. Theres also a great deal of variety out there when it comes to soldering iron tips.

When soldering put the iron tip on one side of the metal and touch the solder to the other side of the metal. A hollow forming in the end of the tip cleaning and re-tinning has no effect or needs frequent repeating. Common signs that the tip needs replacing are.

It would be best if you considered protecting your tip against oxidation. Instead have the solder pads free of oxididized surfaces meaning to remove any protective film shortly before soldering. This conical-shaped tip is the one that more new users to soldering are likely to imagine because it is widely used and conventional in its shape.

Eventually they wear out. Hold the solder to the tip while its heating up to make sure you tin the tip before it has a chance to turn black. Touch the solder to the tip of the iron and make sure the solder flows evenly around the tip.