How To Solder Multiple Wires Together

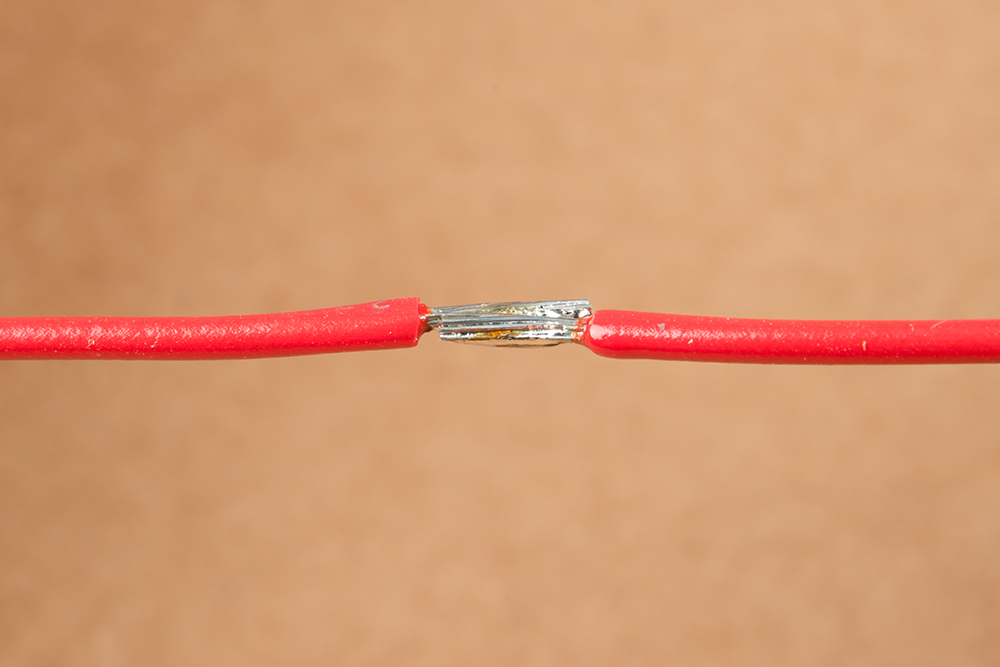

The most secure and durable way to splice two wires together is to solder them.

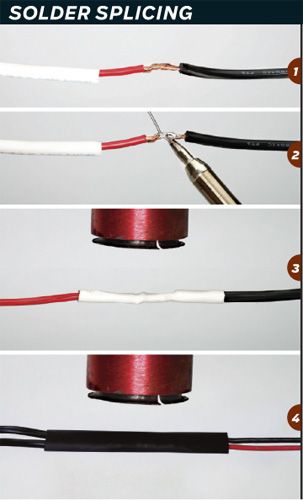

How to solder multiple wires together. Automotive wiring should be soldered and protected properly in order to withstand all types of weather rain snow and salt. After wrapping the wires tightly around each other use a soldering iron to heat the wrapped portion of the wires. There are three main ways to solder wires together.

Youll get a straight wire that has a little sideways bump in it so get a larger shrink tube to isolate it youll need two times the diameter of one wire. When you solder items together youll typically be using the hot metal tip of the iron to melt a small amount of solder alloy around and between the components or surfaces being joined. Heat up the joint and melt the solder with the wire not the soldering iron.

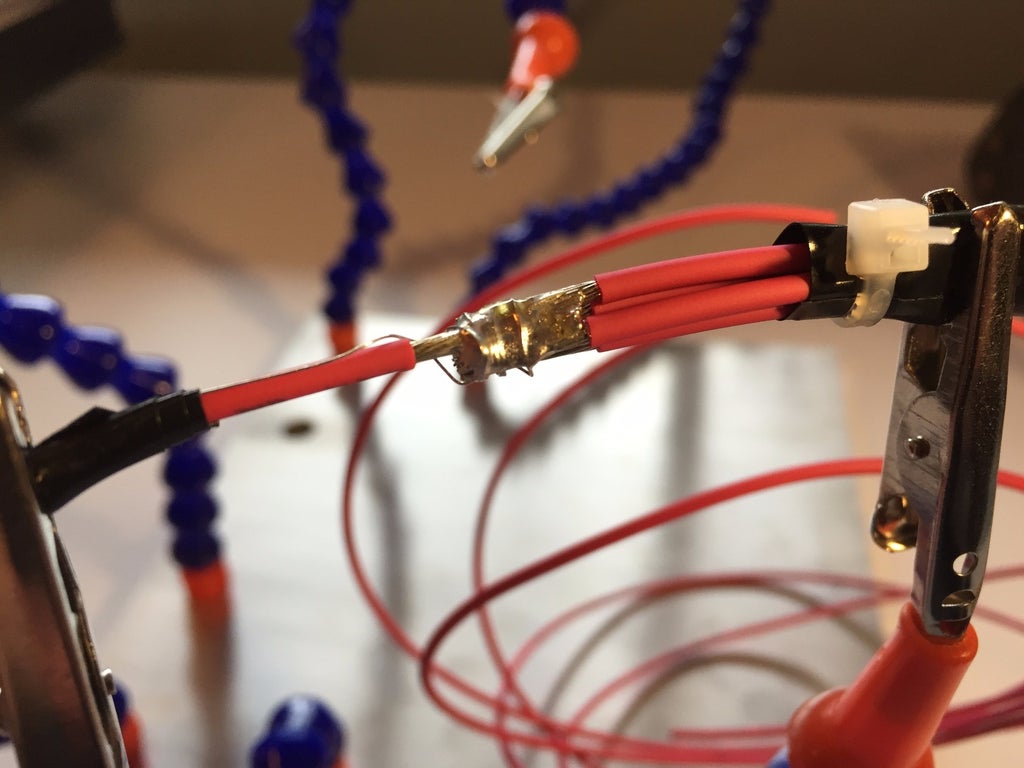

You can also apply some solder. The challenge is holding the wires in place long enough for the solder to cure. You could use a piece of stripboard to solder the wires to and some PCB screw terminal connectors for a neat disconnectable connection to the power supply.

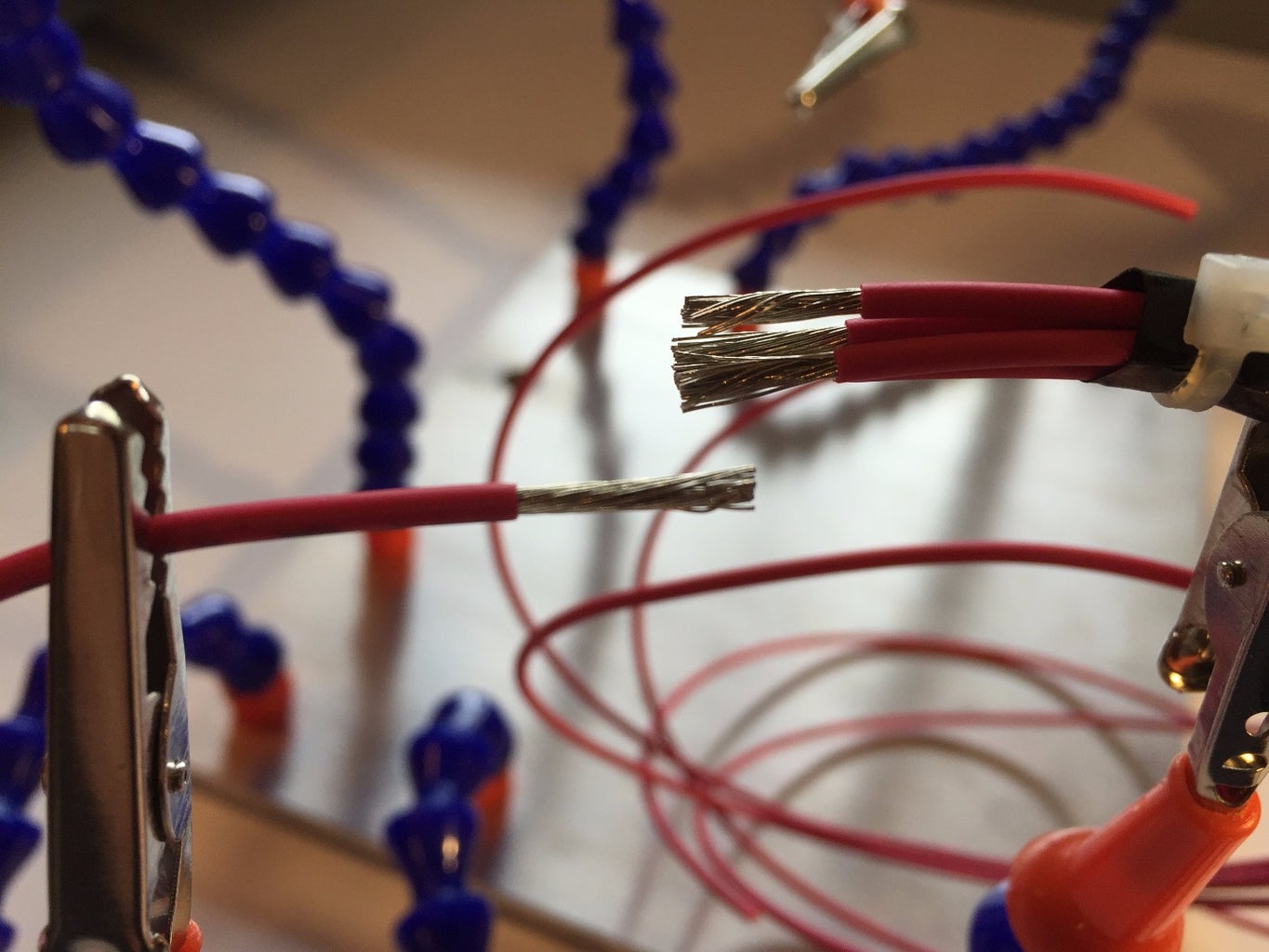

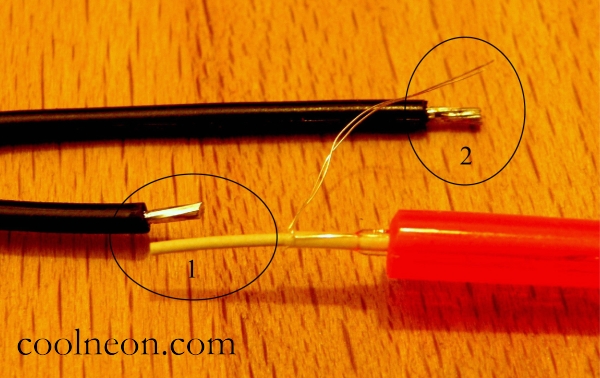

The first two splices require that about a half-inch of the insulation be removed from both of the wire ends. After a couple of seconds apply some solder. 3 Heat the shrink tube to make it shrink down around the wire.

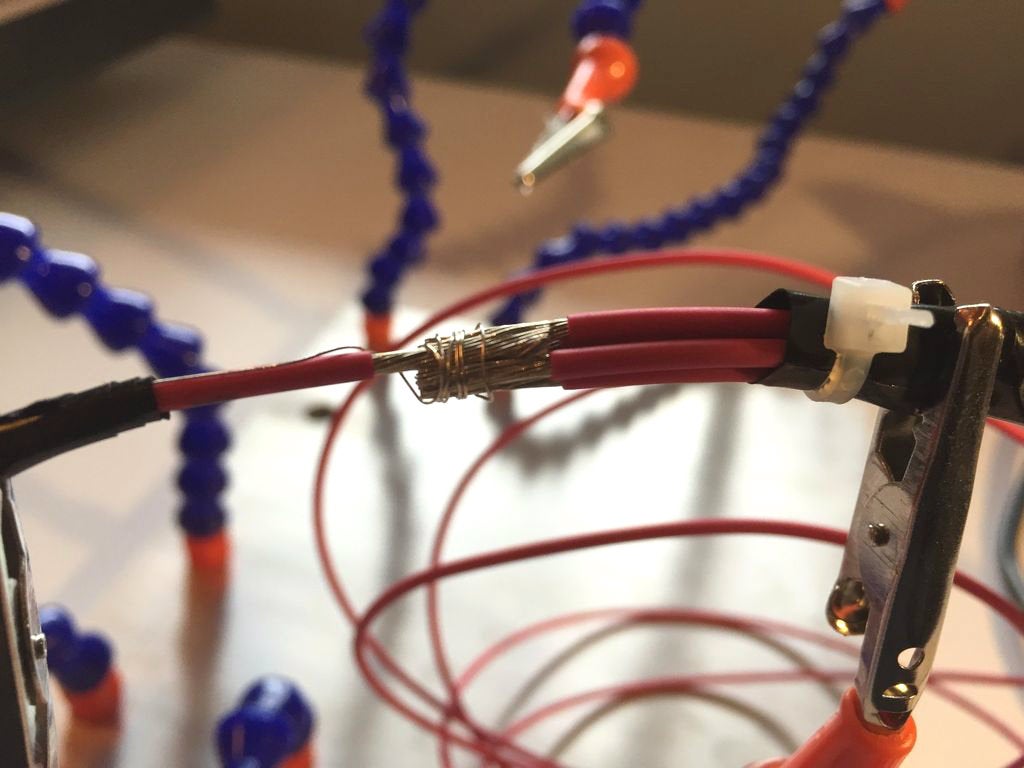

This is also a great way to connect multiple wires to one lead. Another approach that sometimes works is to first use a few turns of much finer wire to hold the two main wires together the whole blob then being soldered. 2 Heat the joint with a soldering iron or pencil from underneath.

The ends are twisted together to form a good mechanical bond between the wires. Make sure your soldering iron is fully heated and touch the tip to the end of one of the wires. The connection of two wires should be covered with solder all around.