How To Solder Fine Electrical Wires

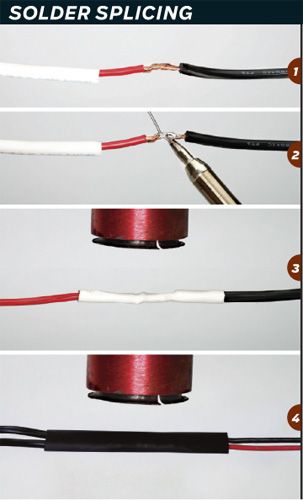

Then twist the filaments of each wire tightly to make them orderly.

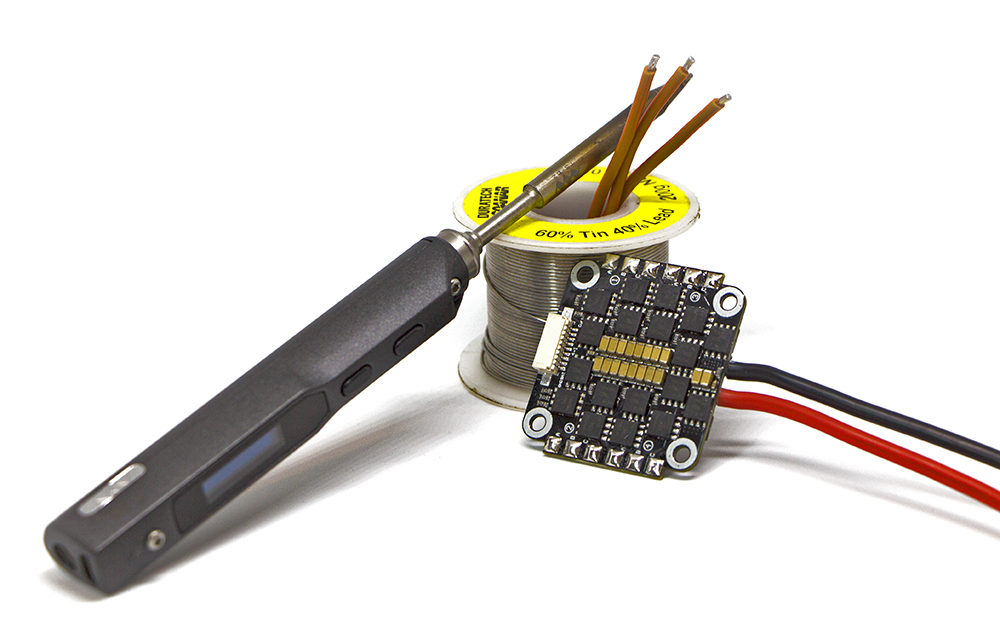

How to solder fine electrical wires. Dodgy wiring inadequate fusing and exposed connectors could lead to a fire. The most reliable way of joining two wires together is by soldering. First you will have to strip off the insulator that covers the wires.

If you use flux it must be for electronics any other will ruin the wire in a short time as most are acid. Please dip the litz wire without removing enamel coating into the soldering jarpot. You need to apply the heat to the metal part on the plug because that takes the longest to heat and melt the solder.

Tin the wire end before soldering to make sure you have most of the insulation removed. These tips work on any soldered wire connection. A clean surface is required for good soldering.

The advantage of solder is that. Tinning the tips of stranded wires holds the fine wires together and makes it easy to connect them to screw terminals or other connectors. Tinning is a process of using a soldering iron to melt solder around a stranded electrical wire.

Do not put the solder on the iron tip as the tip will be hotter than the wire and the solder may not flow into the wire. You may select the dipping time as per your litz wire AWG size as below table. To tin a wire apply the tip of your iron to the wire for a second or two then apply the solder to the wire.

If you have a solder pot then soldering through enamel wire can be. There is one way to twist wires together for soldering- a horizontal twist that yields a continues length of. Once the connection evenly turns the correct silver color of solder remove the soldering iron and allow the joint to cool.