How To Properly Solder Small Wires

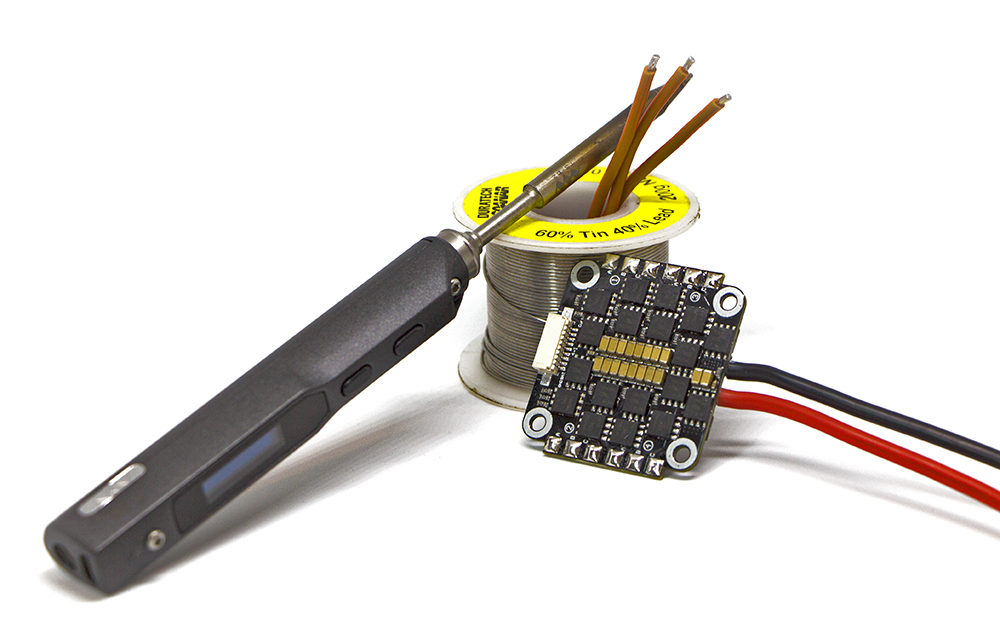

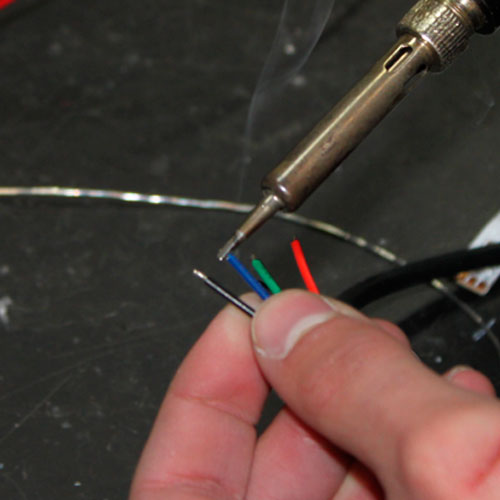

Then connect the soldering iron tip right on the wire.

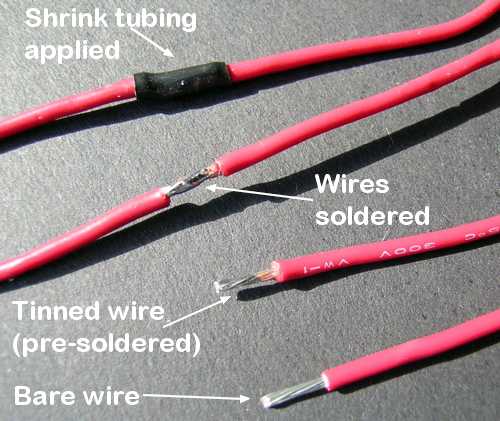

How to properly solder small wires. Just seat them where you want them and find a way to hold them in place with clips or by bending the leads outward slightly so they stay put when you turn the circuit board over. Tin coat with solder the soldering tip first. Solder the Wire Joint.

You have to use leaded solder though because this will pull the enamel wire right onto the center of the pin or pad. Once cooled and hardened the resulting soldered bond or joint is considered to be permanent. Wrap one or two inches of solder around the tip while the iron is cold.

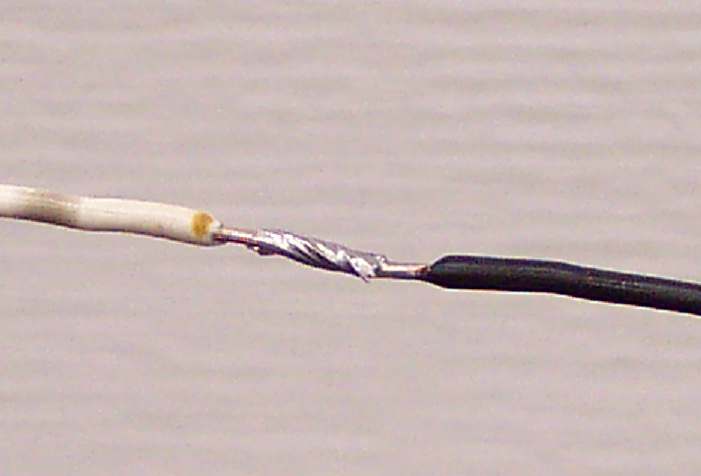

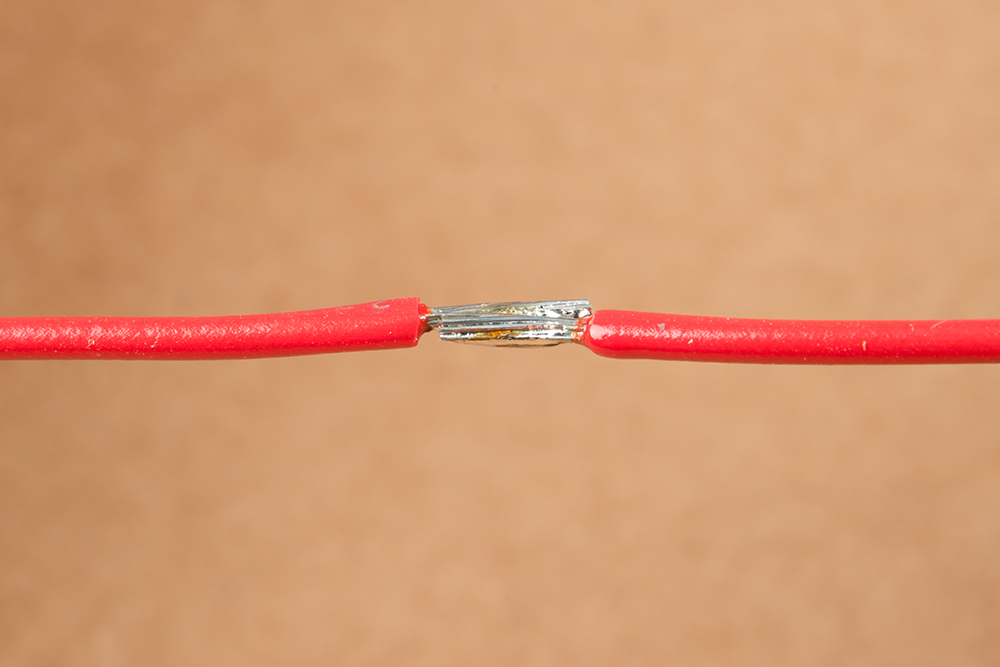

The wires are so small that the solder doesnt really stick so what you have to do is as quickly as possible melt the solder onto the iron but with the joint DIRECTLY in the middle of the two. If your joints are going to be wire-to-wire or wire-to-lead you can twist them together tightly before soldering. The solder should be fed into the cool side away from the heat which allows it to be drawn in smoothly by the heat transfer through the wires.

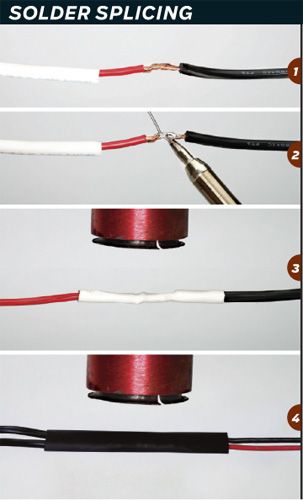

Electrical components placed on a circuit board dont need much prep work. Using a Wire Stripper Strip the Wires to Desired Length. Apply the solder to the top side of the wire opposite the soldering irons tip.

Then remove your hand and hold the twisted section with a plastic stick. Remove the soldering iron and wait a few seconds to let the soldered connection cool and harden. Then touch the tip of the soldering iron to the bottom side of the wire so the solder pool is in contact with the wire.

Instead allow the iron to heat the wire to the point that it melts the solder. Place the tip of the soldering gun underneath the wire and feed a little bit of solder in between the tip and the wire. Pinch the wire tip between the solder and the iron tip to tin and flow the wire end.

/close-up-man-hands-soldering-audio-cable-with-xlr-connector-1078041206-472dd1f03b084f2b9ab373c9dff8080e.jpg)