How To Prepare Soldering Flux

The tinplate metal you want to solder may need some preparation before its ready.

How to prepare soldering flux. The citric acid flux you have made can now be used to prepare metal for soldering. In order for the solder to flow the metal must be clean all of it including the solder and the fluxThe reason for this is that dirt grease oxides etc. It only says For electrical use only.

Do nothing until all of the juice has strained through. It seals out air thus preventing further oxidation and by facilitating amalgamation improves wetting characteristics of the liquid solder. In the soldering of metals flux serves a threefold purpose.

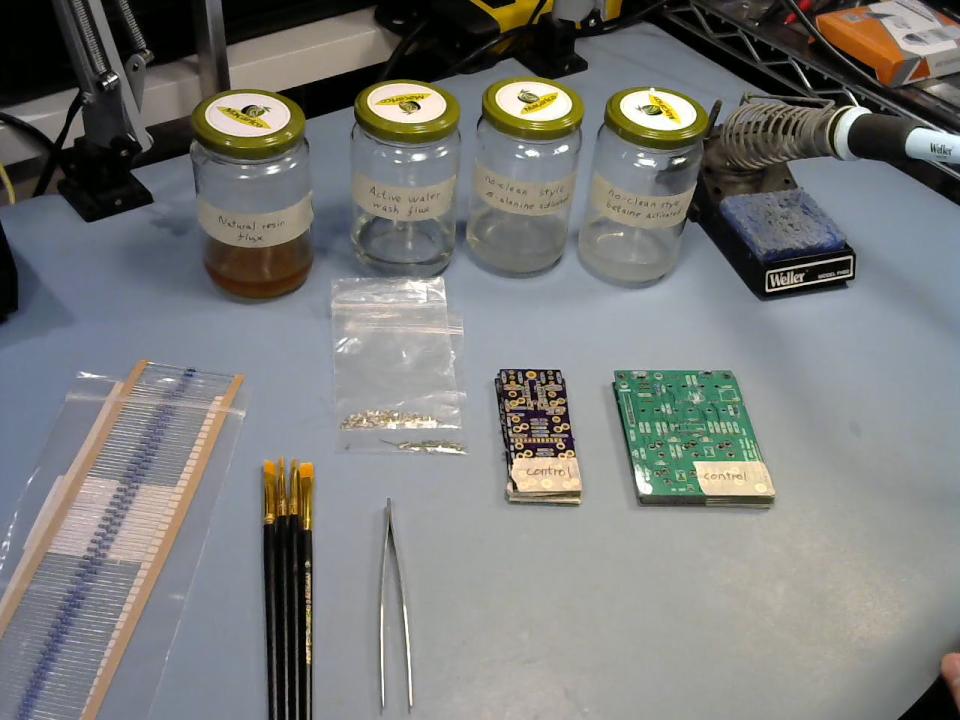

We try it out and then test it by soldering a 28pin SOIC chip. The flux required a preheat temperature of 100 to 130C on the topside of the board just before soldering. Use a small paintbrush or your fingers to scoop up a small amount of soldering flux.

Removing Coating From Metal. If there is a coating over the metal it will have to be removed. Will create a barrier between the metal and the solderThink of the dirty surface like plastic wrap over your ham sandwich your potential solder join.

This process will help improve the heat transfer from the iron to the item youre soldering. Pinecone flux can be made with 10-15 pinecones and some denatured ethyl alcohol. Flux is also formulated to remove any oxidation from pipe and actually etches pipe surface in preparation for the soldering process to be successful.

Spread the flux over the area you will be soldering making sure to cover the wires fully. The flux offered a density of 08 gml and a solid content of 15 percent. You can use a flux pen to dispense flux.