How To Improve Soldering Process

Thus the following are some essential tips to improve your soldering skills.

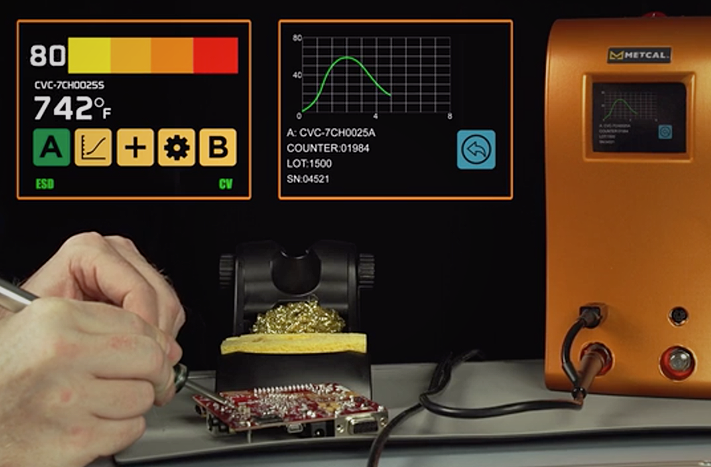

How to improve soldering process. The use of the correct solder solder flux and avoiding oxidation are all important components of the soldering process. The aim of the process is to form acceptable solder joints by first pre-heating the componentsPCBsolder paste and then melting the solder without causing damage by overheating. Increasing soak time will help equalize your soldering temperatures and eliminate trouble spots allowing for good wetting of both the pads and component leads.

Increasing time above liquidus will help to allow for the complete flow of the liquid solder before it begins to freeze. Preheating of PCBs is done using hot air heaters. Before starting tin the soldering tip by adding fresh wire solder to it.

After cleaning wipe the tip with moist cotton or sponge. Thermal shocks occur when the temperature rises suddenly. The process must be adapted acco rding to the design mass size component.

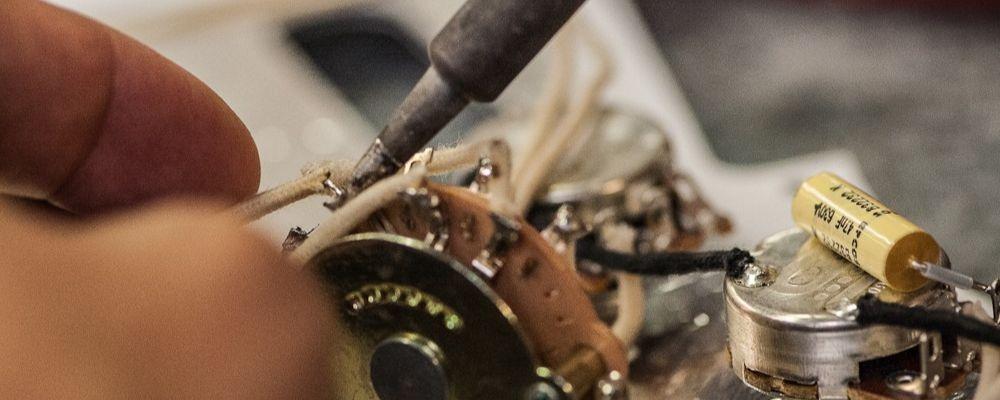

This process will help improve the heat transfer from the iron to the item youre soldering. Enhance the board strength. To prevent burning your ngers use needle nose pliers heat resistant gloves or a third hand tool to hold small pieces.

Good soldering is influenced by how clean the tip of your soldering iron is. In a drag process a stable solder flow is critical. Before you can start soldering you need to prep your soldering iron by tinning the tip with solder.

The basic principle is to make the amount of solder ball printed in the outermost row or four corners of the BGA more than that of the remaining solder balls. Reduce conveyor speed to increase solder contact time Increase flux volume applied reduce air knife pressure Use more active flux systems such. Be careful that give too much of the solder paste volume under the BGA will bring solder short.