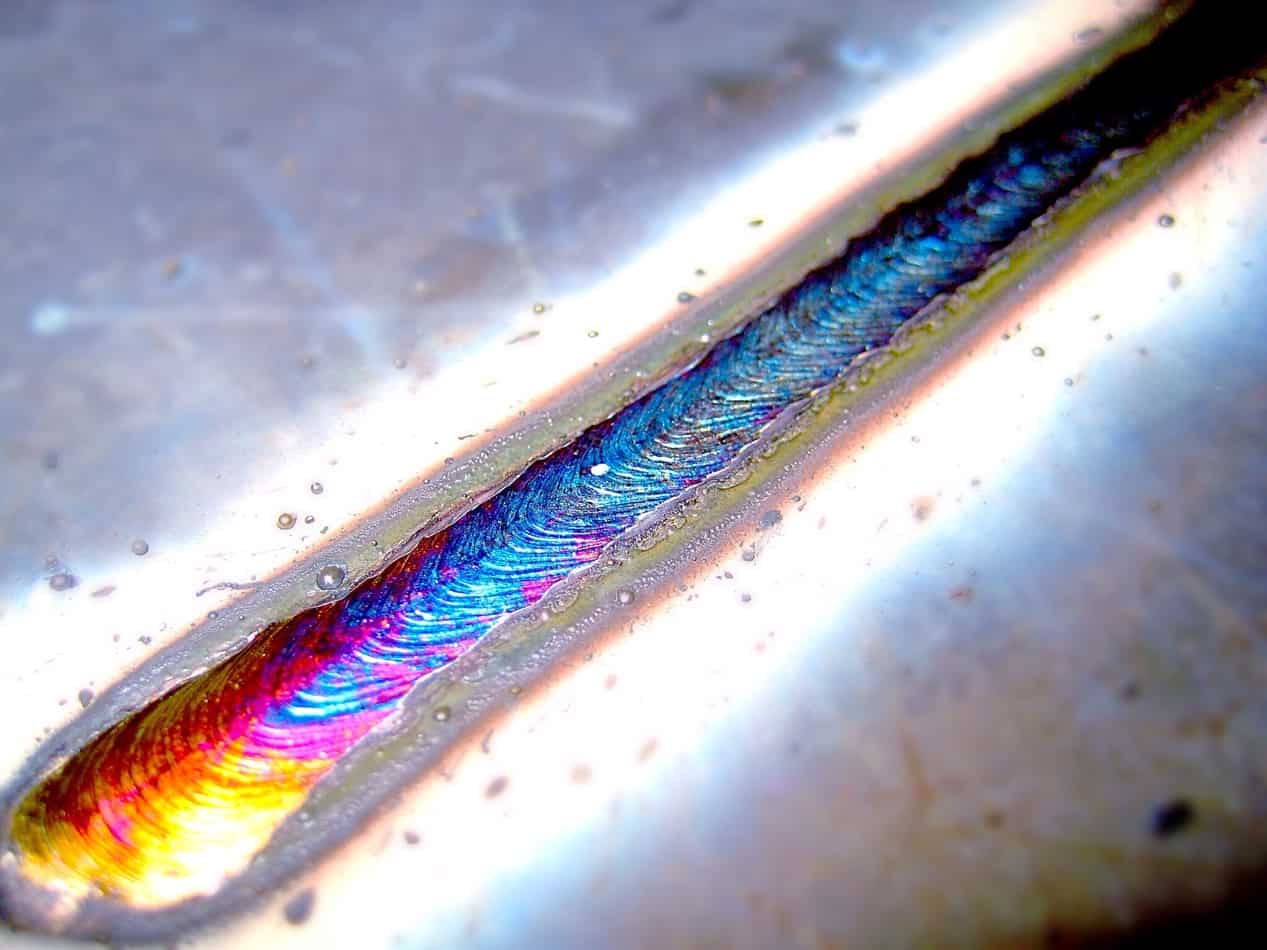

How To Improve My Tig Welding

TIG Welding is one type of welding amongst a few choices you have - MIG Stick Oxyacetylene etc.

How to improve my tig welding. Posted by 5 minutes ago. In TIG the arc length is associated with the voltage so with a longer arc the voltage increase consequently with a shorter arc the voltage decrease. I found using them improves coverage.

Hold the rod so it rests horizontally at approximately a 15-degree angle to the workpiece. These lenses evenly distributes gas to help in the prevention of oxygen contamination as well as allow you to properly work in those heard-to-reach areas like the K T and Y joints. Using an inverter power source is one of the first steps you can take to improve TIG welding efficiency.

Inverters operate by switching high-voltage low-amperage alternating current AC into direct current DC back and forth at a very. Gently but quickly dab the filler metal in the weld pool after heating up the. Use clean dry filler rod.

Clean the scale off the metal before you weld it. Some welds work better with a point while others need a rounded tip. If it is at all possible use gas lens as they will improve shielding gas coverage as well as offer you better joint accessibility which should greatly improve your TIG welding efficiency.

For the beginner it may be a very intimidating process. Im 14 and just started I keep my auto-darkening helmet to go to around shade 10 in dark-state and I dont know what Im doing wrong to not be able to see the weld puddle that is present during welding. Selecting the right tungsten type and size cup size and shielding gas and gas.

Relatively new to Tig welding any advice on how to improve would be greatly appreciated. No matter what field youre in from pipe welding to prototype fabrication there is going to come a time when a joint is going to require you to weld. I keep an assortment of wood and metal blocks near my welding bench and I often can get better support by positioning a block to rest my torch hand on.