How To Improve My Stick Welding

Also make sure to remove any rust moisture oil or any kind of impurities from the surface of the metal before welding.

How to improve my stick welding. LEARNING TO STICK WELD LEARNING TO STICK WELD No one can learn to weld simply by reading about it. The following pages will help the inexperienced welder to understand welding and develop his skill. As a general starting setting I use one amp per thousandth of an inch thickness of the electrode.

Shellfish can make you a better welder. Simply think about CLAMS. For example with a 18 inch electrode thats 0125 inch or 125 thousandths.

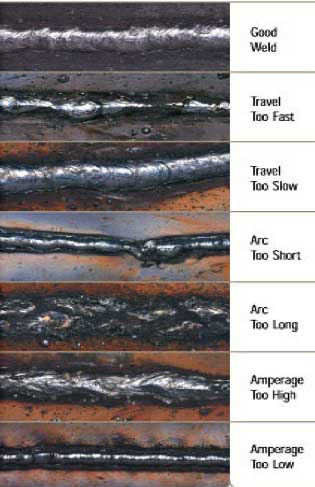

With the correct current set on the welder machine you should get smooth neat welds with little or no splatter. Flat or 1G you drag the rod between 10 to 30 degrees in the direction of your movement. Use a wire brush or grinder to remove dirt grime or rust from the area to be welded.

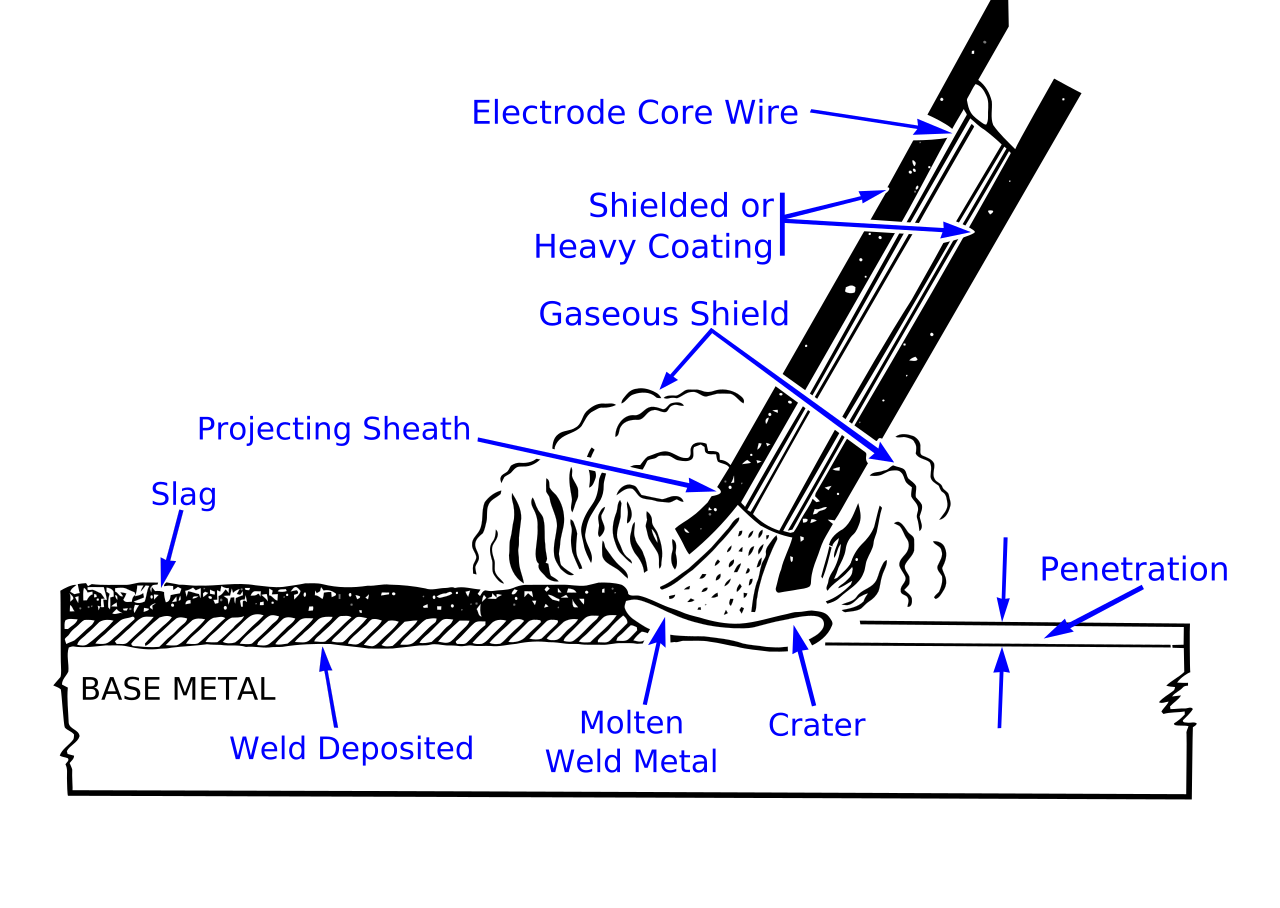

A beginning stick welder can produce better welds by paying attention to the five basic elements to establish a good consistent technique. When you chose the DCEN polarity you will increase your weld penetration. When stick welding for the first time most people find it logical to have a long arc usually to have a better view of the weld puddle.

HAZ or Heat Affected Zone. Remove the welding stinger from the electrode as fast as you can turn off the welder and break off the rod from the metal. At this stage the only thing you can do is to break off the rod from the metal the tip of the electrode which includes the flux might fall off but you dont need to worry too much about it.

Return to Share a Welding Tip. When you pull you can see the puddle but its hard to see where you are going because the nozzle blocks your view. If youre just learning the stick process technically called shielded metal arc welding SMAW remembering these five points will improve your welding technique.