How To Fix A Broken Soldering Tip

If the plug is cooled down pull out spout and the coupling to the plug replace the plastic guide and screw on the plug.

How to fix a broken soldering tip. The solder melts and should stick at the tip. This trick simplifies the soldering process and enables the goldsmith to do better work faster and with fewer mistakes. Heat it up to around 350C and wait.

If playback doesnt begin shortly try restarting your device. Open the Soldering Iron Carefully. The reason why its going black is because there is nothing on the tip to heat - ie.

Otherwise the Soldering Tip may Break. Step 5 Trim to fit. Allow the chain to cool pickle and clean up as needed.

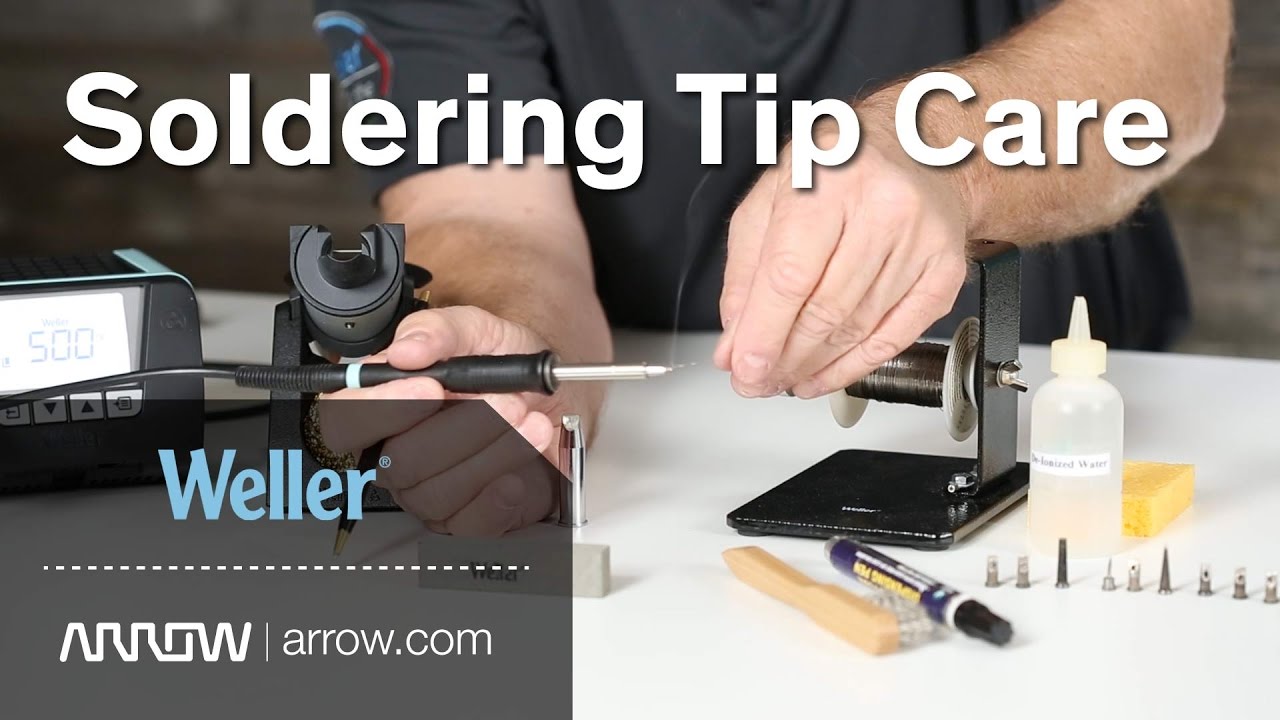

When the solder flows again a small amount of solder will transfer to the joint. If that gives you sound it means you lost connectivity while soldering the ground and you will need to heat up the solder and remove it with the solder pump or wick. Copper wool this is used to clean up your soldering tip such as left over flux and solder on your iron.

Female RCA plug also. In basic applications though electrical tape wrappings work fine. Then fully melt these pieces of plastic by pressing them with the soldering iron tip until they are liquefied.

An overheated joint results from solder failing to flow and the burnt flux residue can make repair very difficult. Best to clean the tip again and then apply some Solder directly to the tip. Then you will need to try again.