How To Clean Solder Flux Residue

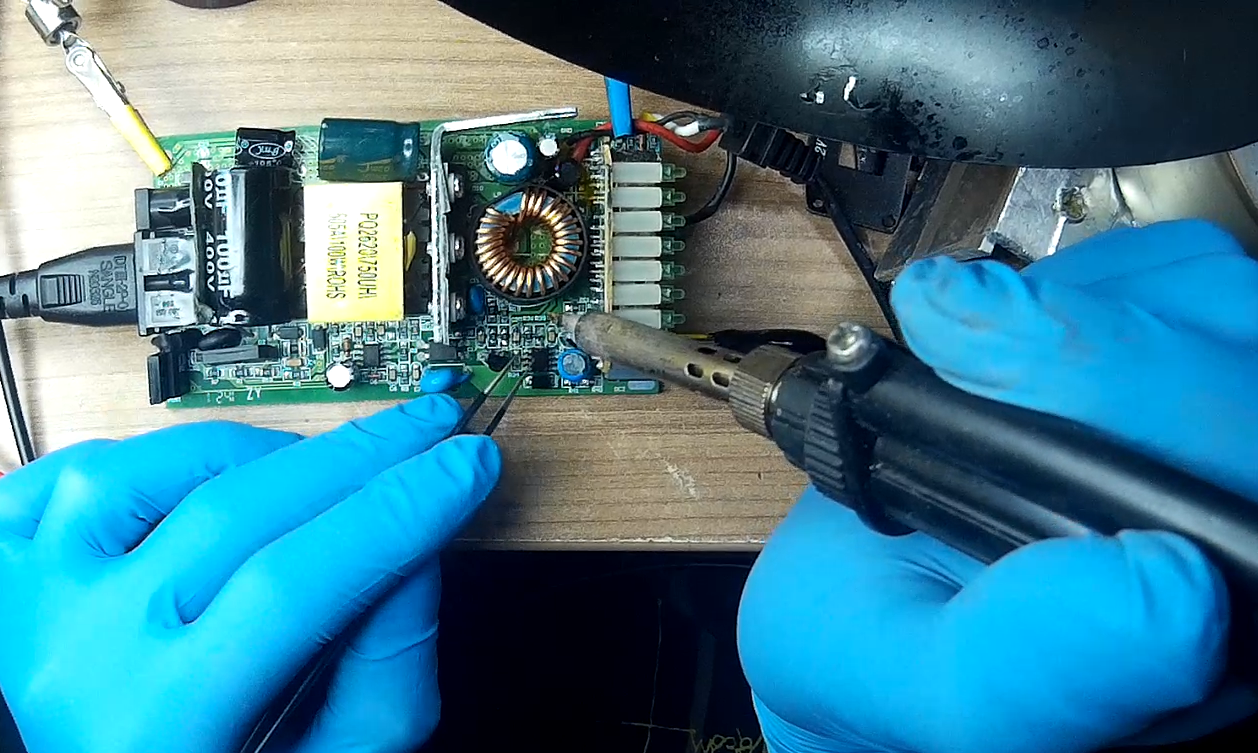

If I just soldered the board I literally just have to dunk it in an ethanol bath gently swish the PCB around to agitate things a bit and tip it as I take it out.

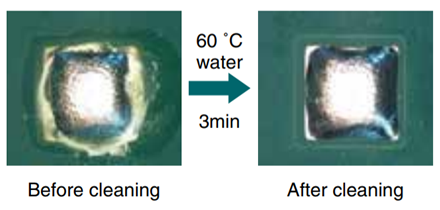

How to clean solder flux residue. Do not use too much pressure as this may cause the solder point to break. Then rinse it with water and pat it dry. Most no clean pastes require an organic saponifier for effective flux removal but.

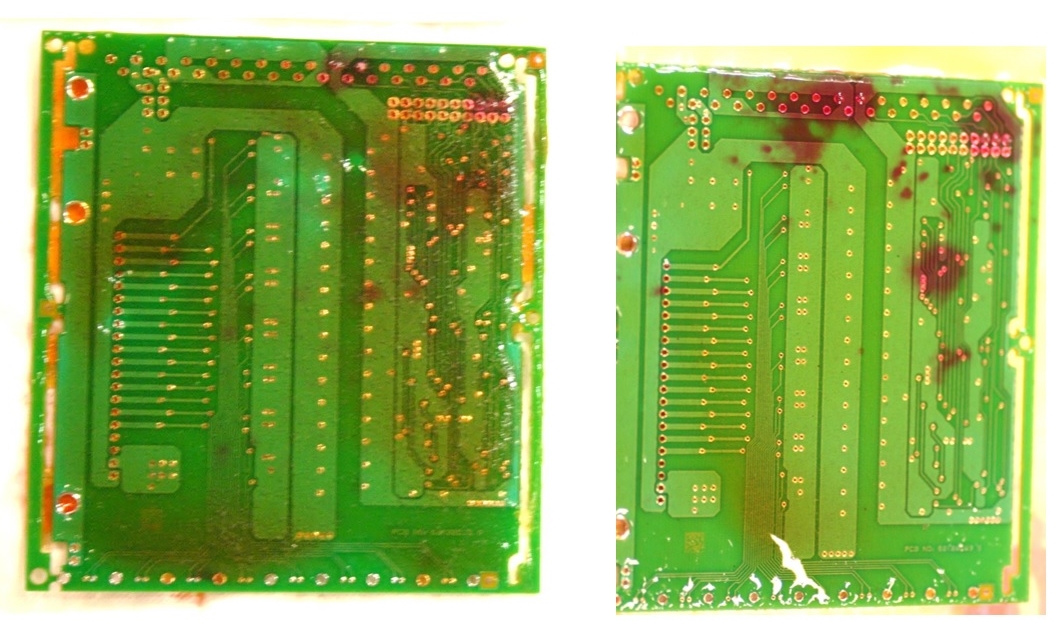

It utilizes a paste flux that is applied using stencils or printers. It is the acid that is making the cooper oxidize and turn green and as stated needs washed. Assuming the assembly will accommodate local cleaning some methods simply cut the residue concentration by spreading it across a larger surface area.

Look for paste that uses aqueous flux or is labelled as NC no clean. Flush with lots of clean water to rinse away any residue. Usually no-clean flux cleans up nicely with isopropyl alcohol or distilled water.

CJs Flux Removeris designed specifically to do this. For studying the effect of flux residue on ECM C33 capacitors were dosed with no-clean flux by dipping in the flux solution. The dissolved flux residue sticks to the wipe and is therefore not spread around the board.

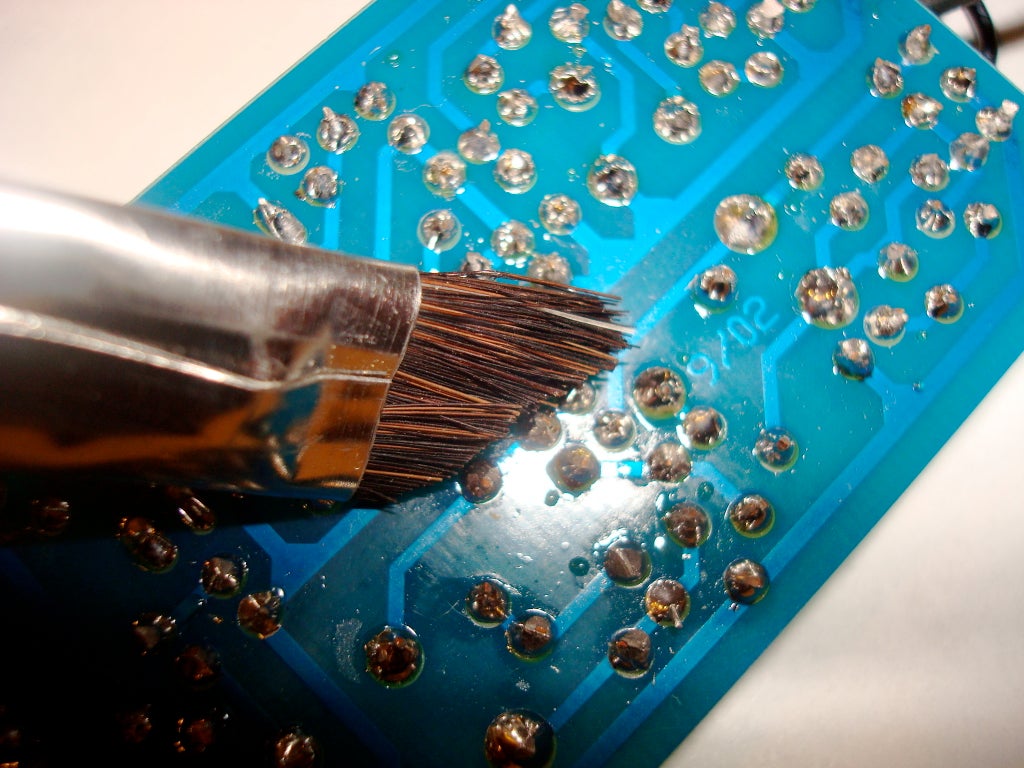

If this is wave soldering using a different temperature profile will solve this. Removal is generally accomplished by thorough washing in warm detergent. Using a paint brush cleaner works for cleaning flux residue too.

Flick away excess by flipping your wrist two or three times. You can submerge the assembled board in a container that is filled with this and agitate it for some 30 sec. I use Kester 44 activated rosin flux core solder Sn63Pb37 031 for most of my soldering.