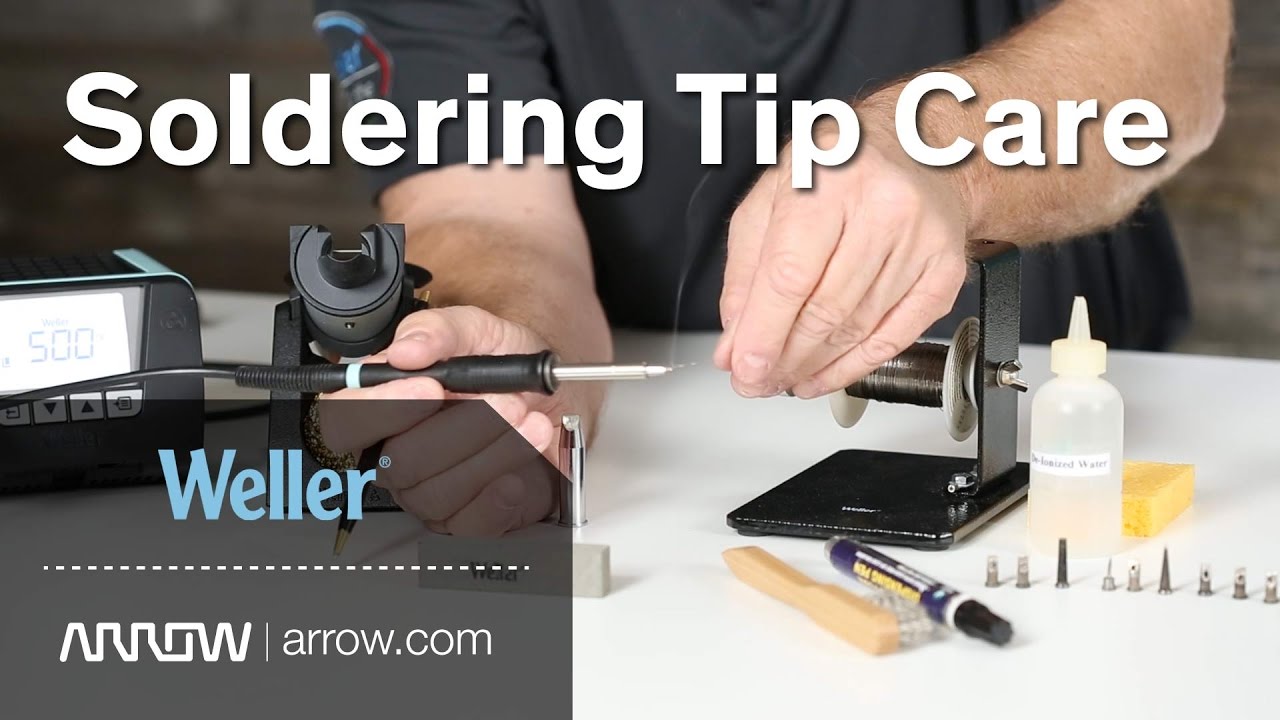

How To Clean A Weller Soldering Iron Tip

For very fine SMD solder joints you may repeat this.

How to clean a weller soldering iron tip. Tip the soldering iron downward and the loose tip should now fall out. The sensor element Weller part EC229A is in a black plastic housing at. This step will coat the iron in a mixture of flux and solder.

Switch on the Soldering Station or the Iron and Make sure it is Hot Enough. The end of a thin metal probe which extends up through the heating element. It may last for years even with heavy soldering.

How to Tin or Re-Tin Soldering Iron Tip. Leads from the 5 conductor cord two wires to sensor two to heater ground. Use fluxes Spongeless and metal wool to remove small amounts of contaminants from your soldering iron tips during soldering circuit board or any other components.

Melt some good quality of solder wire on the Tip. Use a damp sponge to clean the tip and wipe it off quickly to avoid cooling the tip excessively. Clean the tip After every cycle and before you start to solder always clean your tip.

If the tip is interchanged with different sizes frequently. You can also use stainless steel pot scrubber as long as it is dry to prevent transmitting the heat. After trying both the sponge and flux to clean the tip of your soldering iron sal ammoniac would be the next step if the others didnt work.

The best tip tinner is your solder--tips should always be coated with a small amount of solder. Use stainless steel wool flux and thick clothe to clean the tip. Turn off your solder iron and let it cool down for 15-20 minutes before cleaning the tip.