How To Carve A Wood Sign Larger Than Your Cnc Router

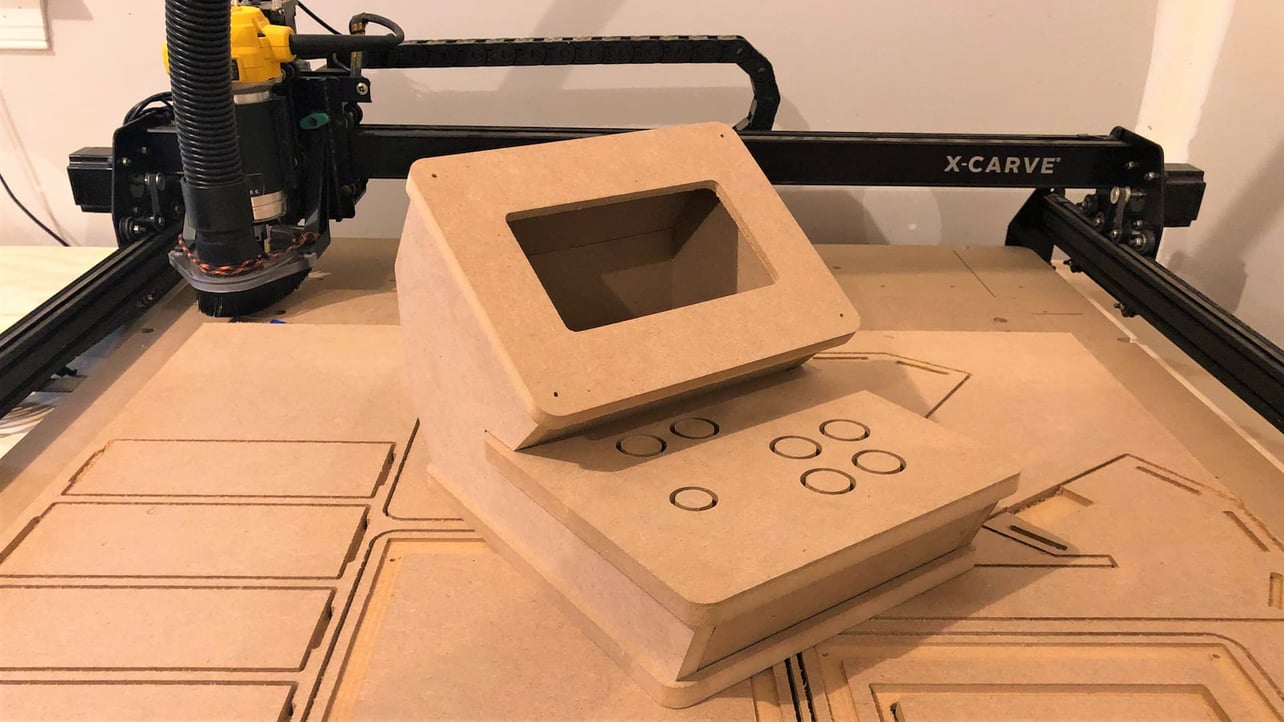

Ive come up with this method while I was making my own DIY CNC router MkII.

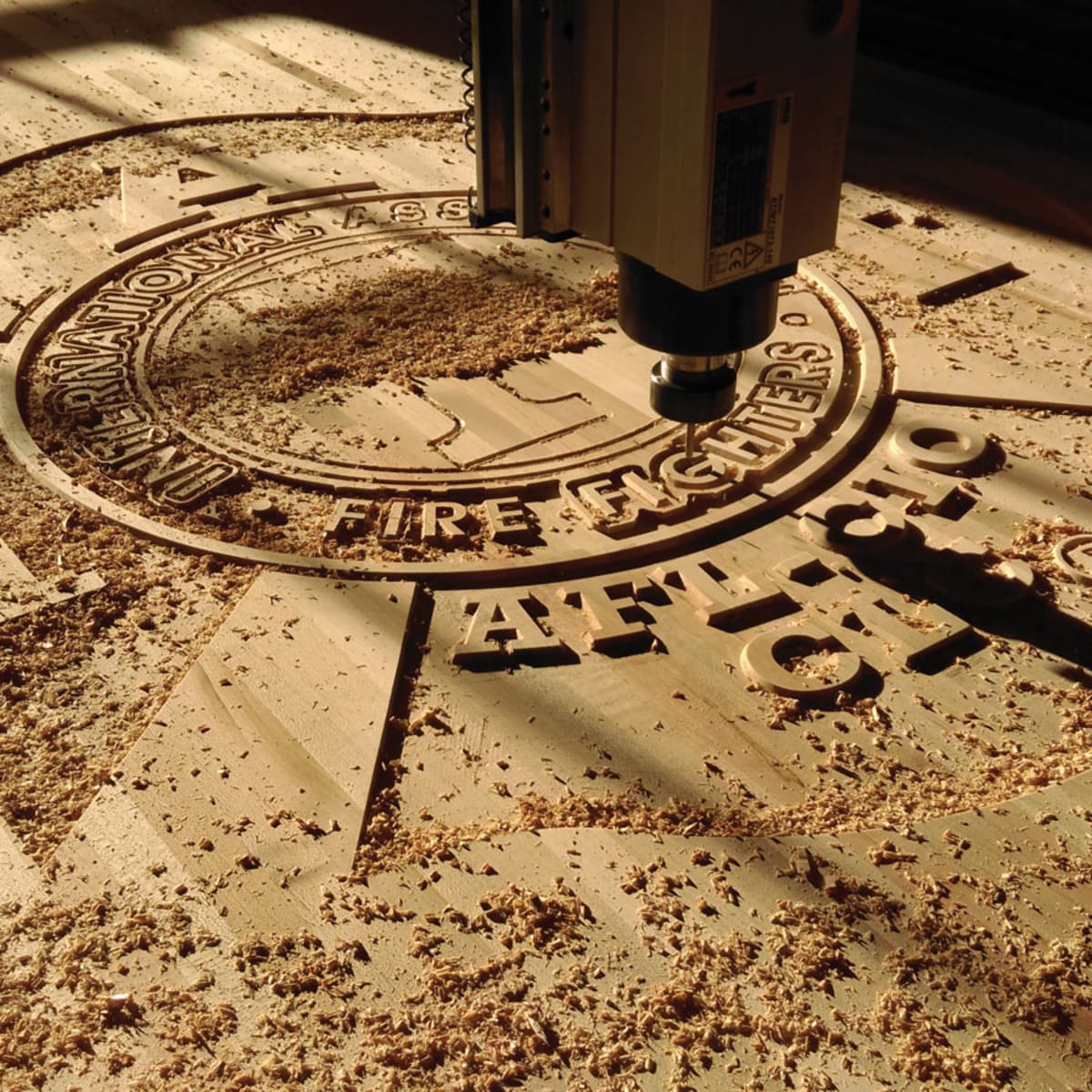

How to carve a wood sign larger than your cnc router. Ornate cabinet doors carved insets all can be programmed on a CNC router delivering a timeless hand carved look at a fraction of the time and cost. This is due to the weather elements. Building your own 3-Axis CNC router is both fun and educational.

Ad sign is a necessary need for nearly every business. Thankfully most programs including the one we used will show a simulation of the cut and let you know if the bit you choose will cut out the shape or if its to large and you need to use a smaller bit. Custom Wooden Name Signs.

In both case a much larger project can still be achieved by breaking the toolpath down into manageable tiles or strips each of which can fit within. It has a flat-edge tip that leaves you with a better edge quality than other bits. Our signs can be cut in unique shapes or carved with a custom design.

I recently upgraded to a 2 12 bit and I love it. Custom Wooden Name Signs are made from a variety of wood types. With a clock face.

Using the Toolpath Tiling options it is possible to machine objects and designs that are many times larger than the available area of your CNC machine bed. If you are flattening large boards or you are responsible for maintaining the spoil board on your CNC router youll want to have a spoil board cutter or flycutter bit. These plans document all the steps I followed to make my DIY CNC Router.

This is the second DIY CNC Router I made after learning a lot from building the first version. Combining art skill tooling and machinery. The CNC wood routers are widely used in woodworking industry.