Do Soldering Tips Wear Out

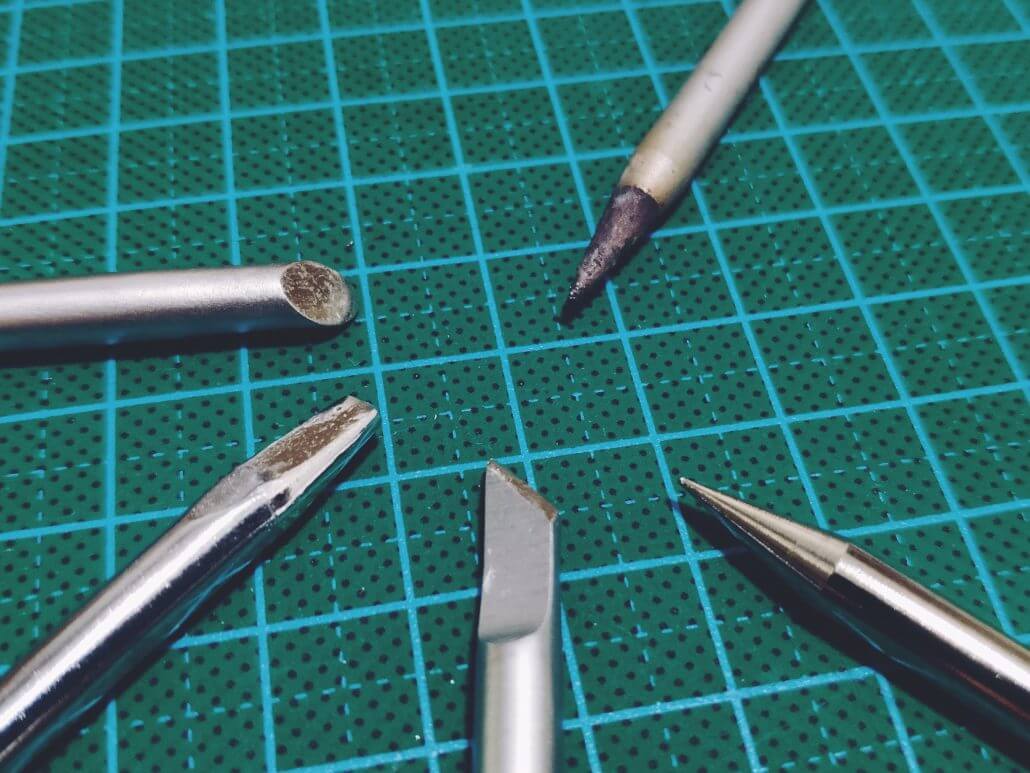

Most tips can be reshaped using a small fine file to clean up the tip and re-tin it with solder once you heat it up.

Do soldering tips wear out. Protecting your solder tips can start as early as from the beginning of a solder tips lifetime. Leaving solder on the tip gives more solder volume for the copper to disolve into. Yep thats about it but I prefer brass wool over damp sponge since I find the sponge tends to thermally shock the plating allowing solder to dissolve the tips core.

Its inevitable for soldering tips to wear out over time and need replacing. However by taking good care of your soldering iron tip you will be able to boost its longevity significantly hence saving your money and improving your soldering skills. To reduce the erosion wipe off the tip between soldering to remove any drops of solder.

Regards JBC Soldering SL. Yes I use the a cleaning wire the one for the dishes since the wet sponge cools the tip and corrodes it faster. Eventually they wear out.

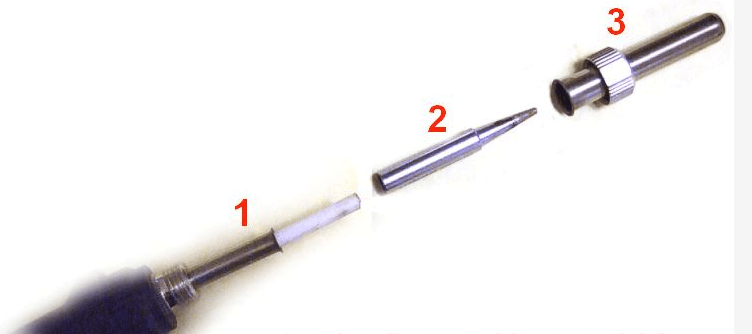

THEN it gets clad. Common signs that the tip needs replacing are. You should tin the tip of your iron before and after each soldering session to extend its life.

The best option is the combination of both as you can see in this JBC tip cleaning stand image. A hollow forming in the end of the tip cleaning and re-tinning has no effect or needs frequent repeating. Abrasion from rubbing the tip against pads RF shields component terminations or pressing against trimmed leads.

Common signs that the tip needs replacing are. Because of this manufacturers of soldering iron tips do not generally warrant plating life. All tips eventually wear out due to heat and normal use.